Heater for semi dry flue gas desulfurization system

Semi dry flue gas purification technology is a high-performance and multi effect

Classification:

Special VOCS energy-saving equipment

Hotline:

Heater for semi dry flue gas desulfurization system

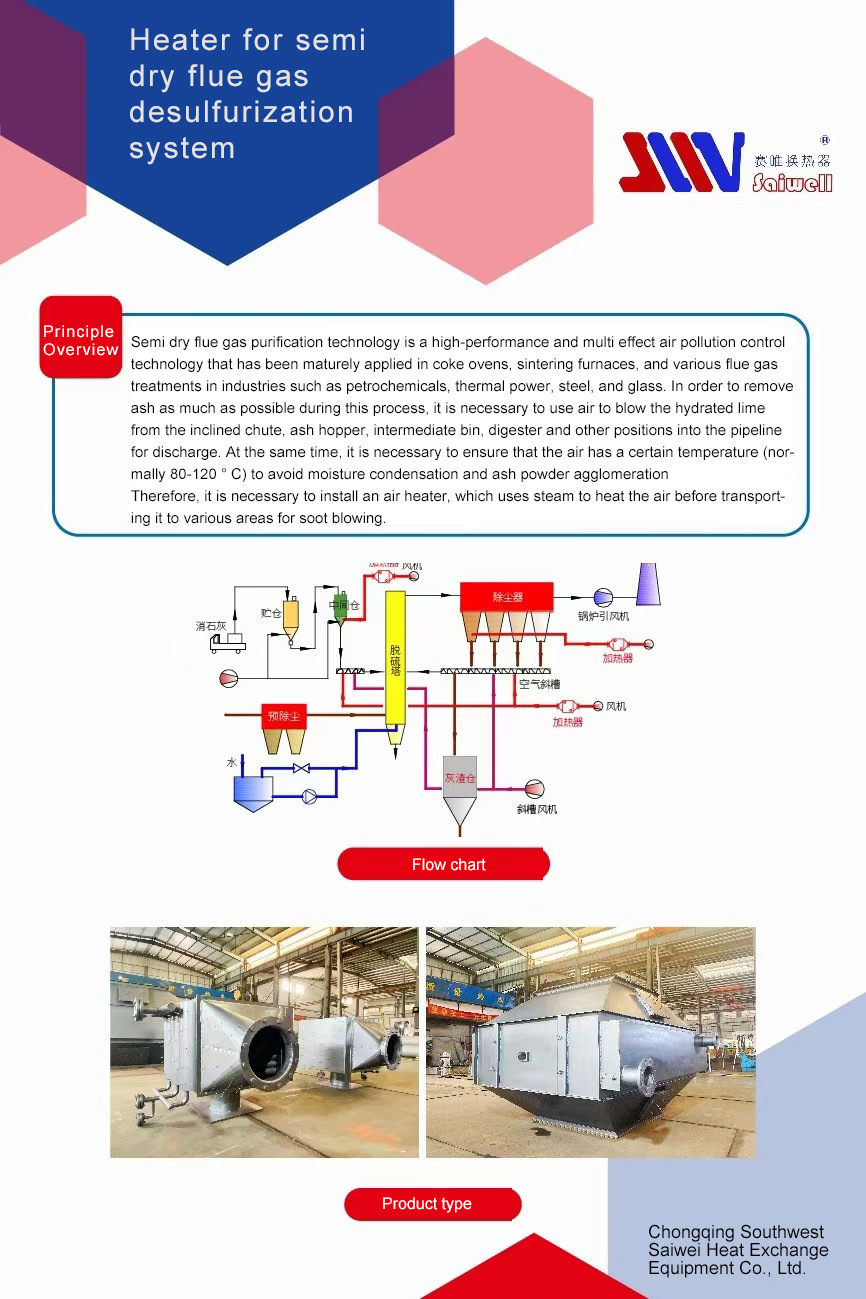

Semi dry flue gas purification technology is a high-performance and multi effect air pollution control technology that has been maturely applied in coke ovens, sintering furnaces, and various flue gas treatments in industries such as petrochemicals, thermal power, steel, and glass. In order to remove ash as much as possible during this process, it is necessary to use air to blow the hydrated lime from the inclined chute, ash hopper, intermediate bin, digester, and other positions into the pipeline for discharge. At the same time, it is necessary to ensure that the air has a certain temperature (normally 80-120 ℃) to avoid moisture condensation and ash powder agglomeration. Therefore, an air heater must be installed to heat the air with steam and then transport it to various areas for ash blowing.

Previous:

Tube fin heat exchanger for cooling or dehydration of compressed gases

Related Products

Related Products

Messages

Your voice is crucial here. Whether you have valuable suggestions for our products and services, encounter questions that need to be answered, or want to share your usage experience, we are always willing to listen.